Asphasol TDS

suggests

Don’t see the Asphasol you’re looking for?

We make several Asphasols that are not listed here.

Connect To KhavaranParaffin

Asphasol

Table of Contents

- Asphasol

- Properties and features of Asphasol

- Ease of use, with a wide range of performance benefits

- Get the performance of sulfonated asphalt and pay 25-50% less

- AsphAsol has overwhelming performance advantages over alternatives

- Proven to reduce torque and drag

- Unique bonding and plugging properties prevent formation damage

- QUICK REFERENCE GUIDE FOR APPLYING ASPHASOL ADDITIVE

- MIXING GUIDELINES

- Pre-mixing

- Pre-mixing in Freshwater

- Pre-mixing In High Salt Muds RIG Sit Mixing

- Download TDS File

AsphAsol

Performs in WBM like sulfonated asphalt. Costs 25-50% less.

Asphasol is a cost-effective, high-performance additive effective in a wide range of water-basedsystems for both low and high temperature wells. Asphasol is renowned as an excellent shale stabilizer.

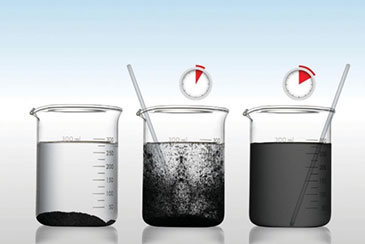

Asphasol disperses quickly and easily inwater-based muds

Asphasol is a free-flowing powder that mixes easily through the hopper and disperses with only mild agitation. It is tolerant of contaminants and eliminates the need for additional surfactants or coupling agents.

Properties and features of AsphAsol

At our production centre we have the flexibility to filter and add to the products to cater for customer requirements.

- Free-flowing powder resists clumping

- Compatible with most water-based systems

- Disperses with mild agitation

- A naturally occurring, mined material

- Effective in both low and high temperature wells

Ease of use, with a wide range of performance benefits

- Mixes easily through the hopper

- Controls fluid loss and seepage

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore

- Minimizes differential sticking

- Maintains lubricity in tight formations

- Is safe and environmentally friendly

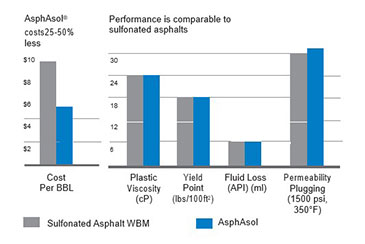

Get the performance of sulfonated asphalt and pay 25-50% less

AsphAsol performs comparably to sulfonated asphalt at a much lower cost. Plus, AsphAsol requires no additional surfactantsor coupling agents, so it further lowers costs by allowing you to use fewer additives.

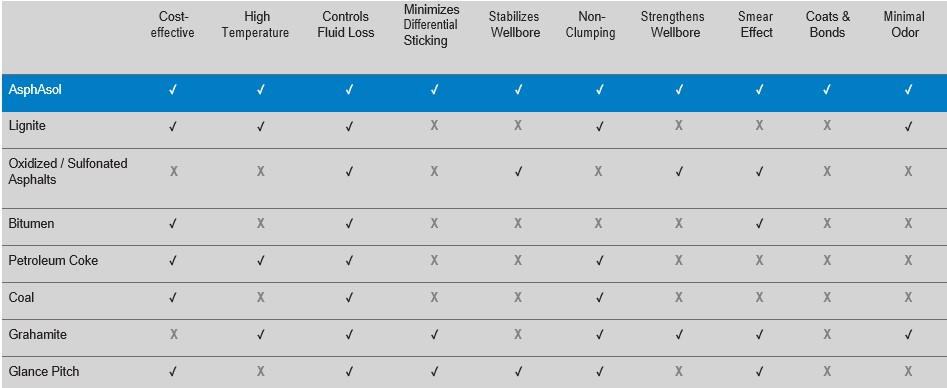

AsphAsol has overwhelming performance advantages over alternatives

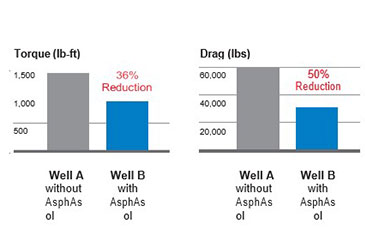

Proven to reduce torque and drag

In the South Pass Area of offshore Louisiana, the operator wanted to reduce torque and drag. Wells in this area are normally deviated approximately 30° from vertical and are drilled with a conventional lignosulfonate mud.

- Well A: Conventional and bead-type lubricants were used for torque and drag

- Well B: 3-4 ppb of AsphAsol were added at approximately 10,600

Upon measurement, the torque on well B was reduced 36% and drag was reduced 50%. Caliper log comparisons from the two wells indicated substantial improvement.

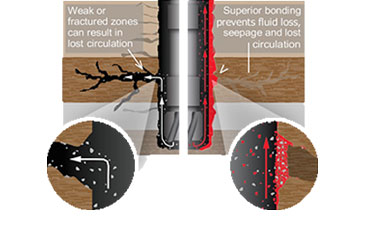

Unique bonding and plugging properties prevent formation damage

Effective at controlling hole enlargement

Hole enlargement is a problem for wells drilled in the South Pars Area. On average, hole enlargement was approximately 50% in the 12.25 inch holes. Once 4 ppb of AsphAsol were added to the conventional water-based formulation, holeenlargement was reduced to 15% in the same section.

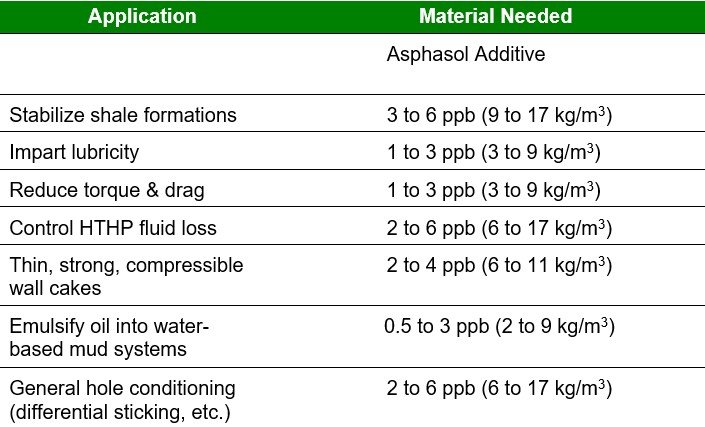

QUICK REFERENCE GUIDE FOR APPLYING ASPHASOL ADDITIVE

MIXING GUIDELINES

If excessive product losses are being experienced over the shakers, it is recommended to employ coarser screen sizes during initial stages of product addition, and then switching over to finer sizes. It is not uncommon to experience a 10 to 20% loss over shakers during initial stages of additions, and in some areas may be considered normal and within acceptablelimits.

Asphasol solubility is much dependent upon temperature, and circulation time. Asphasol will more rapidly mix into the mud system as the fluid temperature increases. If the mud is very cool, it may be best to hold offa dditions until it has a chance to warm up. An amount of Dilution may also be required during initial additions. Continual additions of Asphasol will be needed to maintain a sufficient concentration in the system if losses occur while drilling. Asphasol is consumed while depositing on drilled solids and on the well bore. It is advisable to add 50% more, one day following the initial treatment, to ensure adequate concentration. Use a conventional hopper when chlorides do not exceed 60,000 ppm. When adding to high salinity systems, pre- wetting the Asphasol with fresh water by adding through a chemical barrel or pre-mix tank will improve results.

PRE-MIXING

Asphalt materials (including Asphasol Additive), may have some preliminary losses over the shaker. Precautionary actions to eliminate or reduce this possibility may be necessary. Pre-mixing is recommended even if the product is not running over the shakers, as the thorough solubility before mixing with whole mud, leads to better hole stability. If Asphasol Additive cannot be added directly to the system through the hopper, it can be added to the system using a chemical barrel or pre- mix arrangement. Add 40-50 ppb of Asphasol Additive to the base mud and then bleed it into the active system. Agitation, stirring or circulation may possibly be required in the pre-mix tank or chemical barrel topreventexcessivesettling.

Pre-mixingin freshwater is recommended as the bestm ethod, even when adding to an oilbase mud system. Make up salt such as calcium chloride can be added to the pre-mix, but this is usually not necessary as the amount of fresh water added to the system via concentrated pre-mix solutions will benegligible.

PRE-MIXING IN FRESHWATER

Mixing in freshwater might be the simplest and cheapest solution. Mix 40-50 ppb of Asphasol Additive in a slug pit of freshwater. There could be

PRE-MIXING IN HIGH SALT MUDS RIG SITE MIXING

Asphasol Additive can usually be mixed into high salt (60,000 ppm chlorides and up), high density drilling muds without problems if some extra steps are followed. If enough time is available, both products may be added gradually over several days to an existing system allowing both time and temperature and shearing at the bit to disperse the product. This slow addition of the product reduces losses at the shale shaker which would be expected under these conditions. However, if hole conditions require large amounts of Asphasol Additive be added quickly, it is best to prewet the Asphasol Additive with fresh water in a separate mixing tank. In fresh water large amounts of either product up to 200 ppb may be mixed to create a slurry that may be added direct to the mud system without much loss at the shaleshaker.

Download TDs File

You can download the TDS file :

فارسی

فارسی