Wax Emulsion

suggests

Don’t see the Emulsion you’re looking for? We make several Emulsion that are not listed here.

Connect To KhavaranParaffin

wax Emulsion

What Is Wax Emulsion

Wax emulsion is used in woodworking industry to protect wood boards (Particle Board, MDF, OSB) from water. Wax emulsion has anti-dust effect which is important while boards are sawing up or grinding. Application of wax emulsion makes the plate surface smoother and softer which more than twofold increases the operating time of the grinding belt.

Small particle size (about 1-5 micron) contributes to better paraffin wax penetration into the wood fibre and provides more efficient hydrophobization.

Product

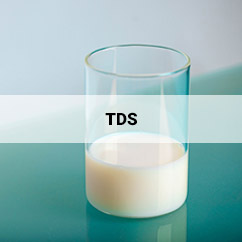

Palayesh Paraffin Khavaran WAX EMULSION is a dispersion of solid wax particles in a continuous phase of water which provide a useful means of delivering wax to a product.

Packing

At our production centre we have the flexibility to filter and add to the products to cater for customer requirements.

Wax emulsion can be supplied in bulk and/or brand new iron drums.

APPLICATION

Wax emulsions are used in the manufacture of paper, paperboard and boxboard.They are used in the production of insulating board, curing, hardboard and particleboard in the building products industry.They are used in woodworking industry to protect wood boards (Particle Board, MDF, OSB) from water.Wax emulsion has anti-dust effect which is important while boards are sawing up or grinding.

Application of wax emulsion makes the plate surface smoother and softer which more than twofold increases the operating time of the grinding belt.Small particle size (about 1-5 micron) contributes to better paraffin wax penetration into the PRODUCT and provides more efficient hydrophobization and other properties needed to achieve.

Quality Control

Khavaran Paraffin Co. guaranty’s the quality of paraffin wax. We welcome our customers to arrange of an international inspector/s such as SGS to check quality and quantity paraffin wax during the production and loading. Alternatively, we can arrange such a service upon request.

In addition some advantages wax emulsion over melted paraffin should be noted

- Small particle size (about 1-5 micron) contributes to better paraffin wax penetration into the wood fibre and provides more efficient hydrophobization.

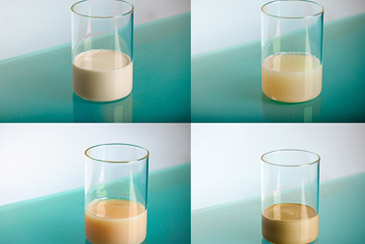

- Wax emulsions mix well with the melamine- and carbamide-based resins. Wax emulsion acts as a water-repelling agent during the hot pressing of plates. The wax emulsion decomposes and melted paraffin wax hydrophobizates the wood plate. Application of special emulsifiers leads to the decomposition of emulsion even before the bending agent becomes hardened which therefore strengthens the waterproof properties of plates.

- Simple method of application cause wax emulsion is liquid.

- No storage expenses – the storage temperature of the wax emulsion is 5-30°C, while for the melted paraffin wax is over 60°C.

- No transportation expenses – in case of using the wax emulsion it isn’t necessary to heat the piping, as no “freezing” occurs inside the pipes.

- Wax emulsions are not fire-hazardous; therefore no fire risk or trauma risk could be caused by its appliance, while such risks could occur in case of applying hot melted paraffin wax.

- Application of the wax emulsion leads to the 10-20% reduction of resins without any worsening of the physico-chemical properties of the plates.

Wax Emulsion

UNIT |

TYPICAL |

CHARACTRESTICS |

|

– |

Liquid of yellowwhite color, without mechanical inclusions |

Appearance |

|

pH |

5 — 9 |

Acidity |

|

– |

50 — 400 |

Brookfield viscosity at 20°C mPa·s |

|

WT% |

53 ± 1 |

OIL CONTENT |

|

– |

280 |

Oil fraction flash point, °C, not less |

فارسی

فارسی